Cost of goods manufactured explained: a guide for product businesses

- Home

- Cost of goods manufactured explained: a guide for product businesses

- by Piyanuch Tangkittipon

- (0) Comments

Cost of goods manufactured explained: a guide for product businesses

Before you crunch the COGM numbers, it’s vital that all the figures you include are up-to-date and as accurate as possible. If the cost and stock levels of raw materials, work in process inventory, and finished goods are way off, COGM won’t solve any of your inventory ills. If you must wait until an entire batch of goods has been sold before calculating your total manufacturing costs, you’ll miss out on opportunities to save money and increase revenue.

- For information on calculating manufacturing overhead, refer to CFI’s guide to job order costing.

- However, what should we include into manufacturing overhead is a complicated matter and doesn’t have a certain answer.

- A high COGM suggests high manufacturing costs, which may imply ineffectiveness in the production process.

- Once goods are manufactured, they move into your finished goods inventory.

- It breaks down all your expenses — materials, labor, and other production costs — so you know where your money is going.

- Additionally, it helps in tracking business development, keeping better financial records, and helps to better manage their inventory.

- It’s all about keeping track of what’s made and what’s sold to keep the business running smoothly.

Chapter 1: Nature of Managerial Accounting and Costs

It helps you see exactly where your money is going in the production process. Successful businesses understand the importance of optimising their cost of goods manufactured (COGM). It’s an essential tool for managing cogm costs, prices, and efficiency, including optimising warehouse space and operations.

Cost of Goods Manufactured Schedule

To calculate cost of goods https://digitalsolution.sa/what-are-expenses-definition-types-and-examples-2/ manufactured, you first need to determine all your production costs and WIP inventory. The COGM formula provides valuable insights into a company’s manufacturing operations, guiding decision-making processes, and facilitating accurate financial management and reporting. COGS is calculated by subtracting the ending inventory from the cost of goods available for sale.

COGM’s Influence on Financial Reporting and Analysis

Accurate COGM calculation ensures competitive pricing strategies and reliable gross margins, safeguarding the financial health of the business. These case studies reveal that with excellent COGM management, companies not only keep production costs in check but also steer the business towards sustainable profitability and growth. The cost of goods manufactured is included in a company’s income statement, usually together with the beginning and ending finished goods inventories. The COGM formula starts with the beginning-of-period work in progress inventory (WIP), adds manufacturing costs, and subtracts the end-of-period WIP inventory balance. With Craftybase, you can easily add your materials, labor, and overhead costs, then see how these costs impact your COGS and final product price. Each element of the equation for the cost of goods manufactured plays a key role in understanding the total manufacturing cost for a given period.

Step 4: Understand the Result

- COGM zeroes in on the sum of manufacturing costs during the production phase, whereas COGS includes all expenses related to both producing and selling products within an identical accounting timeframe.

- Knowing the difference between COGM and COGS helps you manage inventory better and plan for future production needs.

- Managing financial data can quickly become overwhelming, especially when calculating your cost of goods sold (COGS).

- A significant KPI for determining a manufacturing company’s production costs is the Cost of Goods Manufactured.

- Without a clear view of COGM, you risk underpricing key items, eroding profit margins, or misallocating resources in your supply chain.

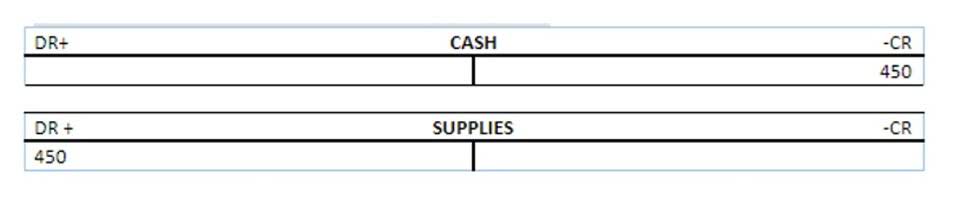

This precision is crucial for both setting the right product prices and maintaining profitability. Your main manufacturing expenses are the cost of direct materials, direct labor, and manufacturing overheads. COGS refers to the direct costs of manufacturing goods that are going to be sold by a company. The amount of COGS includes the cost of materials and labor that were used directly for the production of goods. On the other hand, indirect expenses are excluded from this category of goods.

You need this step because those unfinished products haven’t been sold yet. However, the complexity of manufacturing accounting makes proper COGM implementation challenging. Many manufacturers struggle with work-in-progress valuation, overhead allocation, and integrating financial systems with production data. These challenges require specialized expertise that understands both the shop floor and the financial implications. Your COGM statement transforms raw financial data into actionable operational insights by highlighting material usage variances, labor cost fluctuations, and overhead rates. Direct materials, direct labor, manufacturing overhead, and WIP adjustments.

Create a free account to unlock this Template

Once all relevant data is captured and allocated, the software automatically calculates the total cost of goods manufactured for each production order or batch by applying the COGM formula. COGS is a financial accounting measure representing the direct costs of producing and selling goods. Without knowing COGM, it’s almost impossible for a manufacturer to reduce manufacturing costs and improve profitability. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company’s competitive edge.

What is the cost of goods manufactured formula?

Your ending WIP inventory is the value of unfinished goods at the end of an accounting period. In financial statements, this is carried over from a previous accounting period to become the beginning WIP inventory of a new financial period. Aside from the wages, direct labor also includes the amount necessary for payroll taxes, employee contribution, insurance, and benefits. Many companies use their timesheet logs to see their actual expenses every period. When a business makes use of the data in its COGM, it can be easier to keep and manage its inventory. The beginning and ending balances need to be taken into consideration as well in the same way that the work in process inventory and raw materials are.

Free Financial Modeling Lessons

This means that when it comes to managing your manufacturing accounting, all those numbers will In-House Accounting vs. Outsourcing already be there and ready to go. Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing. The total cost of those three expenses, or the cost of manufacturing, is $40 million.

- Cost of goods manufactured allows you to understand the total cost of all goods made within a given period, whether or not they were sold.

- Yes, COGM provides detailed cost insights, making it easier to create accurate budgets and forecasts.

- Cost of Goods Manufactured (COGM) and Cost of Goods Sold (COGS) sound similar, but they’re not the same thing.

- Knowing how to manage it allows companies to enhance their conditions and eventually make their business better.

- The total cost of those three expenses, or the cost of manufacturing, is $40 million.

By accurately calculating COGM, you’ll gain insights into profit margins, set competitive prices, and optimize your supply chain. Knowing this, 78% of successful online retailers regularly calculate and monitor their COGM. This is nothing but the cost sheet of the company, and it includes prime cost as well.

Leave a Comment